Introduction

In today's rapidly evolving technological landscape, the demand for reliable and high-performing control cables has never been greater. From industrial automation systems to robotics, aerospace applications, and beyond, the need for cables that can withstand repeated bending and flexing without compromising performance is crucial. High flex life control cables have emerged as a solution to meet this demand, offering enhanced durability and flexibility to ensure optimal functionality in dynamic environments. This article will delve into the intricacies of high flex life control cables, exploring their design, applications, benefits, and the impact they have on various industries.

Understanding High Flex Life Control Cables

High flex life control cables are specially engineered cables designed to withstand continuous bending and flexing without suffering from performance degradation or mechanical failure. Traditional cables are not built to handle the rigors of constant movement, leading to premature wear and potential breakdowns in applications where flexibility is essential. High flex life cables are constructed using advanced materials and techniques that enable them to endure millions of bending cycles while maintaining their electrical conductivity and mechanical integrity.

Key Features of High Flex Life Control Cables

1. Flexible Construction: High flex life control cables are constructed using flexible materials such as specially formulated PVC, polyurethane, or silicone compounds that allow them to bend and flex without cracking or breaking. This flexibility is crucial for applications that require cables to move freely without causing strain or damage.

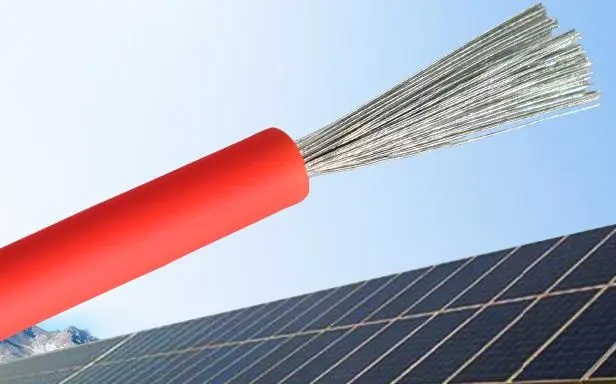

2. Reinforced Core: These cables typically feature a reinforced core, such as stranded copper conductors or fiber-optic strands, that provide excellent conductivity and strength. The use of high-quality materials in the core ensures reliable signal transmission and power delivery even under extreme bending conditions.

3. Protective Sheathing: High flex life control cables are often encased in durable sheathing materials such as thermoplastic elastomers (TPE) or polyethylene (PE) to protect the internal components from environmental factors, abrasion, and mechanical stress. The protective sheathing enhances the overall durability and longevity of the cables, making them suitable for demanding applications.

4. High Flex Life Rating: One of the defining characteristics of high flex life control cables is their ability to withstand a large number of bending cycles without deterioration. These cables are rigorously tested to ensure they can endure millions of flexing cycles while maintaining their electrical and mechanical properties, making them ideal for applications with continuous movement.

Applications of High Flex Life Control Cables

High flex life control cables find a wide range of applications across various industries where flexibility, durability, and reliability are paramount. Some of the key industries that benefit from the use of high flex life cables include:

1. Robotics: In robotic systems, where cables are subjected to constant movement and repetitive bending, high flex life control cables play a crucial role in ensuring smooth operation and longevity. These cables are used to connect sensors, motors, and other components within robotic arms, allowing for precise control and movement.

2. Automation and Manufacturing: High flex life control cables are extensively used in automated manufacturing processes where machinery and equipment require flexible cabling solutions to enable seamless operation. These cables facilitate the transmission of signals, data, and power between different components, ensuring efficient production processes.

3. Aerospace and Defense: The aerospace and defense industries rely on high flex life control cables for a wide range of applications, including aircraft wiring, avionics systems, and military vehicles. These cables are designed to withstand harsh environmental conditions, vibration, and mechanical stress, making them ideal for critical aerospace and defense applications.

4. Medical Devices: High flex life control cables are utilized in medical devices and equipment where flexibility, reliability, and biocompatibility are essential requirements. These cables are used in applications such as medical imaging systems, surgical robots, and patient monitoring devices, where precise signal transmission is crucial.

5. Energy and Power Generation: In the energy sector, high flex life control cables are deployed in power generation facilities, renewable energy systems, and electrical distribution networks. These cables provide a reliable means of transmitting power and control signals in applications that require flexibility and durability.

Benefits of High Flex Life Control Cables

The adoption of high flex life control cables offers a multitude of benefits for industries and applications that demand reliable and high-performance cabling solutions. Some of the key benefits of using high flex life cables include:

1. Enhanced Durability: High flex life control cables are designed to withstand millions of bending cycles, ensuring long-term durability and reliability in dynamic environments. shielded cable increased durability minimizes the risk of cable failure and downtime, leading to improved operational efficiency.

2. Improved Flexibility: The flexibility of high flex life control cables allows for easy installation and routing in tight spaces or applications that require frequent movement. The cables can bend and flex without losing their electrical conductivity or mechanical integrity, making them ideal for challenging installations.

3. Reduced Maintenance Costs: By using high flex life control cables that offer superior durability and longevity, industries can reduce maintenance costs associated with cable replacement and repair. The robust construction of these cables minimizes the need for frequent replacements, leading to cost savings over time.

4. Reliable Signal Transmission: High flex life control cables ensure consistent signal transmission and power delivery even under demanding conditions. The use of high-quality materials and construction techniques results in reliable connectivity and performance, enabling seamless operation of connected systems.

5. Increased Productivity: The reliability and performance of high flex life control cables contribute to increased productivity in industrial applications by minimizing downtime and disruptions. These cables enable continuous operation of machinery and equipment, leading to enhanced efficiency and output.

6. Customization Options: High flex life control cables can be customized to meet specific application requirements, including varying lengths, connectors, and sheathing materials. This customization allows industries to tailor the cables to their unique needs, ensuring optimal performance and compatibility.

Impact of High Flex Life Control Cables on Industries

The integration of high flex life control cables has had a significant impact on industries that rely on flexible and durable cabling solutions to drive innovation and efficiency. Some of the key ways in which high flex life cables have influenced various industries include:

1. Improved Performance: The use of high flex life control cables has led to improved performance and reliability in applications that require flexible cabling solutions. Industries such as robotics, automation, and aerospace have benefitted from the enhanced durability and flexibility of these cables, resulting in smoother operation and increased productivity.

2. Enhanced Safety: High flex life control cables play a crucial role in ensuring the safety of equipment and personnel in industries where reliable connectivity is essential. The robust construction of these cables minimizes the risk of cable failure and electrical hazards, contributing to a safer working environment.

3. Cost Savings: By investing in high flex life control cables that offer long-term durability and reliability, industries can realize cost savings in terms of maintenance, repair, and downtime. The reduced need for frequent cable replacements leads to lower operational costs and improved overall efficiency.

4. Innovation and Growth: The availability of high flex life control cables has fueled innovation and growth in industries that rely on flexible cabling solutions to drive technological advancements. Companies can explore new applications and solutions knowing they have access to reliable and high-performing cables that can meet their evolving needs.

Conclusion

High flex life control cables have become indispensable components in industries where flexibility, durability, and reliability are paramount. These cables offer a robust and reliable solution for applications that require continuous bending and flexing, ensuring optimal performance and efficiency in dynamic environments. By leveraging the benefits of high flex life cables, industries can enhance productivity, reduce maintenance costs, and drive innovation in their respective fields. As technology continues to advance, the demand for high flex life control cables is expected to grow, further solidifying their role as key enablers of progress and efficiency across a wide range of industries.